If you’re tired of overpriced, cookie-cutter filtration systems that don’t fit your needs — why not build your own?

Designing a DIY whole-house water filter lets you control what gets filtered, save serious money, and create a system that’s actually built for your water quality. And don’t worry — even if you’re not a plumbing pro, it’s easier than you might think with the right guide.

Let’s break it all down — step-by-step. 🧠

🧠 Quick Takeaways

- ✅ DIY systems give you more flexibility (and serious cost savings) over pre-built filters.

- ✅ A simple setup can handle sediment, chlorine, heavy metals, or even PFAS.

- ✅ Water testing first is critical — so you target the right contaminants.

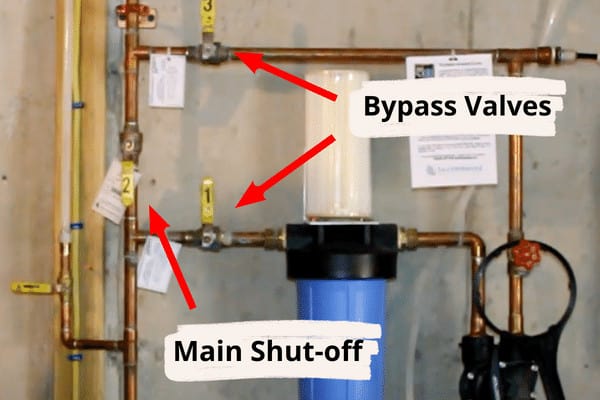

- ✅ Smart add-ons like pressure gauges and bypass valves make maintenance way easier.

- ✅ You don’t have to be a pro — just patient and ready to get your hands dirty.

⚖️ DIY Water Filters: Pros and Cons

Building your own system has big rewards — but it’s not without challenges. Here’s a real look at both sides so you can decide if it’s the right move for you:

| ✅ Pros | ⚠️ Cons |

|---|---|

| Fully customizable to your water quality | Requires research and planning upfront |

| Big cost savings over pre-built systems | Installation takes time and basic plumbing skills |

| Easy to upgrade or expand later | No manufacturer’s warranty if issues pop up |

| Learn valuable maintenance and troubleshooting skills | No guaranteed results unless you test after install |

🧠 Good to Know: You don’t need to build the most complicated setup to get real results. Even a simple two-stage system can beat the pants off cheap “all-in-one” filters you see online.

🛠️ Ready to Build? Start Here

Decided to roll up your sleeves and DIY your water filter? Awesome — here’s exactly how to plan, build, and install your custom system without the guesswork.

If you want a few ready-made ideas to jumpstart your design, check out these excellent multi-stage water filter systems — they’re a great blueprint to build your own from. 🛠️

Now, let’s walk through your custom build step-by-step. 🧰

🧪 Step 1: Test Your Water First

Before you buy a single filter, you need to know exactly what’s hiding in your water.

Different contaminants need different solutions — guessing could leave you stuck with a system that doesn’t actually solve the real problems.

Here’s how to start smart:

- ✅ City Water Users — Your annual Consumer Confidence Report gives a good snapshot of your water quality. But remember, it won’t tell you about issues that happen between the treatment plant and your tap — like lead from old pipes.

- ✅ Well Water Users — Testing is 100% your responsibility. Wells are more vulnerable to contaminants like: bacteria, heavy metals, and pesticides.

- ✅ Best Practice — Don’t wing it. A professional lab test gives you real numbers you can act on confidently.

(Need help? Here’s an easy guide on how to test your water supply).

💬 Good to Know: A $100 water test today can save you thousands later — by helping you choose the right filters (and avoiding systems you don’t actually need).

🛠️ Step 2: Choose Your Components

Picking the right parts for your DIY system is where the magic happens. Here’s what to focus on to get the cleanest, healthiest water possible:

| Component | Why It Matters |

|---|---|

| Filter Housings | Hold your cartridges. Bigger housings fit bigger filters — which means better flow and longer life between changes. |

| Cartridge Filters | Each filter targets specific problems (sediment, chlorine, lead, PFAS). Choose based on your water test results. |

| Bypass & Shut-Off Valves | Make it easy to service your system without shutting off your entire house. |

| Pressure Gauges | Monitor your system’s health and spot clogged filters before they become a big problem. |

| Mounting Brackets & Hardware | Needed to secure the system safely — especially for wall-mounted filters. |

| Drain Lines (If Needed) | Required for systems like backwashing filters and some whole-house RO setups. |

💬 Pro Tip: When choosing cartridges, look for systems that are NSF certified. Certification means they’ve been independently tested to actually remove what they claim.

🧠 Smart Tip: Standard filter sizes (like 10” or 20” Big Blue housings) give you the most flexibility long-term — no getting locked into expensive proprietary parts!

🧰 Step 3: Gather Your Materials

Once you’ve picked your filters and fittings, it’s time to stock up on tools and parts. Here’s what you’ll need to keep the install running smooth:

✅ Plumbing Materials:

- Filter housings

- Cartridges (sediment, carbon, specialty media)

- Pipe fittings and elbows (PVC, PEX, or copper, depending on your plumbing)

- Bypass and shut-off valves

- Pressure gauges (optional but smart)

- Teflon tape

- Mounting brackets

- Drain tubing (for backwashing or RO systems)

✅ Tools Checklist:

- Pipe cutter or hacksaw

- Adjustable wrench

- Drill and drill bits

- Screwdriver

- Sandpaper

- Silicone grease (for O-rings)

- Flashlight

- Bucket and rags for spills

💬 Pro Tip: Before cutting a single pipe, lay out all your parts in order of install — like a dry run. It’ll save you a ton of stress once the water’s shut off!

🛠️ Smart Tip: Don’t cheap out on fittings or O-rings — a $2 fitting can save you $200 in future leaks.

🛠️ Step 4: Assemble and Install Your System

Now the fun part: putting it all together! Here’s how to do it without breaking a sweat:

✅ DIY Installation Steps:

- 🔧 Turn Off Your Main Water Supply: Always start safe. Shut off the main valve before making any cuts.

- ✂️ Cut Into the Main Line: Use a pipe cutter to carefully create space for your filter system.

- 🧽 Prep the Pipe Ends: Sand the edges smooth and wrap threads with Teflon tape for leak-free seals.

- 🚰 Install Shut-off and Bypass Valves: Add control right at the filter — no need to shut down your whole house if maintenance is needed.

- 🔩 Mount Filter Housings: Attach brackets securely to the wall or frame to support the weight of filled filters.

- 💧 Connect Your Filter Stages: Flow typically goes: Sediment → Carbon → Specialty Media (like KDF or Catalytic Carbon).

- 🧼 Prime and Flush Filters: Follow manufacturer directions to flush cartridges or media before full use.

- 🚿 Reconnect and Restore Water Supply: Turn the water back on slowly and check for leaks around every fitting.

- 🔍 Pressure Test and Fine-Tune: Monitor gauges (if installed) and adjust settings if needed. Tighten fittings if you spot any drips.

💬 Good to Know: If you’re adding a UV light or backwashing filter, it should be the last stage — protecting your drinking water from bacteria after all other contaminants are removed.

🛠️ Pro Tip: Save yourself future headaches — keep a small wrench kit and extra O-rings nearby for quick fixes later on.

🔍 Step 5: Test, Tune, and Celebrate

Before you pop open a cold drink to celebrate, you’ll want to double-check that everything is running like a champ. Here’s how:

✅ Final Testing Checklist:

- 🚰 Open Water Supply Slowly: Let water flow gently at first to avoid pressure shocks on new fittings.

- 🔍 Check Every Connection: Visually inspect each joint, pipe, and housing. Even tiny drips can turn into big problems later.

- ⚙️ Cycle Through Filter Modes: If you installed a bypass valve or multiple stages, flip through the settings to make sure water flows properly.

- 📈 Monitor Water Pressure: Use installed gauges (or eyeball it) — if pressure seems too low, it could hint at a clogged cartridge or a loose fitting.

- 🧼 Flush New Filters: Run water for 5–10 minutes through the system to clear out any carbon dust or media fines.

- 💧 Taste Test: Pour yourself a fresh glass from a tap — it should taste clean, crisp, and free of any chemical odors.

💬 Good to Know: New carbon filters often release a little harmless black dust at first — that’s totally normal. A quick flush clears it up.

🛠️ Pro Tip: Keep a notepad handy to jot down the installation date of your filters. Setting reminders for cartridge changes later will save you time (and keep water quality high).

🧼 Final Thoughts

Building your own whole-house water filter isn’t just a smart move for your wallet — it’s a game-changer for your water quality and peace of mind. 🚿

From custom filter choices to long-term savings, a DIY setup puts you in full control of what’s flowing into your home. And with today’s easy-to-find, NSF-certified components, you don’t have to be a master plumber to make it happen.

- ✅ Start by testing your water.

- ✅ Choose the right filters for your needs.

- ✅ Install with care — and monitor for years of clean, safe water ahead.

It’s more than a project — it’s an investment in your: health, your home, and your future. 💧🏠

150 people found this helpful. Was this guide helpful to you?

150 people found this helpful. Was this guide helpful to you?